We eat a lot of bacon. Even our vegetarian meals tend to have a strip of bacon. And I save every drop of grease. How could I not? I grew up with a mug of bacon grease in the fridge for frying eggs in the morning. This was ironic because we otherwise avoided animal fats (the fat-free craze was gaining speed at that time). Instead we used Imperial Margarine (Canada’s premier butter-substitute) for baking and ‘buttering’. Except for potatoes and popcorn – those were butter. I guess my parents just made this stuff up as they went a long.

The margarine of my youth

And apparently I follow in their footsteps, making stuff up as I go along based on the information available to me. I bake and spread butter, I fry coconut or olive or peanut oil. I eat lots of ‘healthy fats’ (i.e., avocados, nuts). But I never use the bacon grease.

For a few years I wanted to use beef fat to make soap. I had been making cold process soaps for a few years, always using plant oils. I inquired at a few deli/butcher counters for beef fat – which makes a hard, white soap, clean soap. But no-go. I gave up.

Meanwhile, the bacon grease continued to build up in the kitchen. And in the garage. Random yoghurt and ice cream containers stacked in corners, leaking. Occasionally I would relent and throw them out.

It finally occurred to me to make soap from the bacon grease. Duh! Except that I didn’t know how. Gods bless the Internets. Just a little bit of searching and I found a saponification value for bacon fat (the g/g ratio of lye needed to neutralize and convert particular fatty acids into soap molecules) and instructions on preparing the oil.

BUT! Just because I knew how didn’t mean I was ready to start – no, no, no! That is not how perfectionist procratinators proceed! I had to wait until Scott said ‘Enough – do something with these or I am throwing them out’. At last I could leap into action.

Can full of bacon grease ready to melt

The first step was to clean the fat. Anyone who makes bacon understands that bacon grease is ‘dirty’. It is full of crunch black bits and stinks. You don’t just want to throw that stuff into soap. So I started cleaning the grease.

Melted, bacon grease turns dark and transparent

Step 1: Pour the melted bacon grease into the water and boil with salt (this instruction comes back to haunt me)

This steps produces the first miraculous transformation. I let the mixture cool after one hour of low boil; first in the ‘airlock’ and then in the fridge, until I had a firm layer of fat covering the top of my pot.

After first boil, a hard layer of dirty fat sits atop nasty dirty stinky chunky water

Step 2: Discard water and repeat with clean water

I pried the fat up and was able to lift it out with a spatula. Underneath was a nasty, smelly bit of brown water with chunks of meat (you vegetarians feel free to retch). I threw that in the compost and started over again. This time, the fat layer didn’t smell, there were no more chunks, but the water was a deep amber-brown and smelled horrid.

After the second boil, clean, low-odor fat

Firm fat layer removed from the second boil

No more chunks, but the boil water under the fat is dark and stinky

Step 3: Repeat until water is clean

The third time around, the water was nearly clear. But there was a problem: the fat layer was getting progressively softer, to the point that I could no longer lift even chunks of the lard out with the spatula. What was I doing wrong?

Third boil water is ‘clean’, but fat (in background) is too soft!

I had been wondering about the salt, added ‘to help absorb smell’. No one said how much to add. Well, what does salt do? Maybe by making the water more dense it helped the fat float to the top? I wanted good separation, so I reasoned that if some salt was good, more was better.

After a fourth boil, with even more salt – super soft fat!

When my fat was getting softer, not harder, I thought again. What else might the salt be doing? It breaks up the hydrogen bonds among water molecules. Could it be emulsifying the fat? Some inet searches turned up saltwater as a potential emulsifier of grease. Oops.

I re-boiled the bacon fat in water (no salt) several times, each time getting a more solid layer of fat. I stopped at ‘good enough’, with a nearly solid layer and very clean water. The fat layer, which had stopped smelling early on in the cleaning process, had reacquired some stink during the over-salting quilombo, but I decided to proceed. The fat no longer smelled of nasty old bacon fat – it now smelled like chicken stock. I could work with that.

Prior to this adventure, I have used a mixture of at least three (and up to six!) plant oils to make soap. It is a messy tedious process to prepare the oils – some are liquid, some solid, and each require precise weighing. By contrast, using bacon fat was simple. I just weighed my prepared patty, calculated the amount of lye and water I needed, and I was ready to start.

To calculate the amount of lye, multiply 0.1388 times your weight of fat. I had 710 g of fat, so would need 99 g of lye to completely convert the fat to soap. But I always superfat my soap; adding a bit less lye to a) ensure the lye is used up, b) make the soap more moisturizing. So I went with 85 g of lye. I dissolved this lye in twice as much water (170 g).

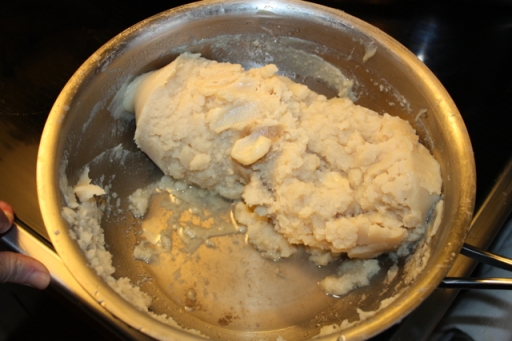

Cleaned bacon fat melting in soap pot

Soap Step 1: Melt the fat

You want the fat liquid, and warmed but not hot. For this recipe, the fat should be 88F.

Measuring the water and lye

Soap Step 2: Dissolve the lye in water

Wearing protective clothing (especially glasses), slowly add the lye to the water, stirring ( I use my stainless steel thermometer). The exothermic reaction generates a lot of heat, so cool the lye solution in a cold water bath.

Soap Step 3: Add the lye solution to the fat

When the lye solution and the fat are about 88F, slowly add the lye to the fat, stirring vigorously (but take care not to splash).

Soap Step 4: Stir until ‘trace’

You can use an immersion blender to speed things up at this point. I wanted to see how long it would take to trace, so I stirred by hand for 20 minutes. I can’t say I saw trace, but there was no sign of separation, the solution was noticeably thicker, and I had to go to dim sum. Next!

Soap Step 5: Add essential oils (optional)

I debated leaving the soap plain, to see if it really had no odor, but – what if it did? Plus, it’s always nice to have a pleasant-smelling soap. So I added a few drops of rosemary essential oil and stirred the solution a bit more.

Vitreous quality of freshly poured soap

Soap Step 6: Pour into prepared mould

For my ~2c of fat, I used a 10″x10″ box, lined with saran wrap. Wrap the box in old towels (in case of any leaks) and store somewhere warm. If soap dries too quickly a powdery lye film can form on top.

Several hours after pour, soap is matte and becoming firm

Soap Step 7: When soap is firm, cut into bars

Check the soap periodically over the next day. Cut it when it is the consistency of hard fudge. Overnight is usually as long as you want to wait.

Next morning, soap is firm enough to cut

Soap Step 8: Wait 2-6 weeks for your soap to cure before using it

Although the physical changes are rapid (soap is firm within a few days), the chemical process of saponification is more slow. Right now the soap is still very basic (high pH) and will burn your skin if you use it. This is because there is still lye in the soap. It will take several weeks before the lye has completely broken down the fatty acids into soap molecules. At this point, the lye will be completely used up and the soap will be composed of soap molecules, glycerin, and some residual fats. Soap can be ready after 2 weeks, but 4-6 weeks is a safer period.

In May, I will let you know how the soap performs. So exciting!!

Lessons Learned:

- Using bacon fat for soap is awesome

- Most of the time spent cleaning the fat is waiting for it to harden

- Use a small amount of salt (~1 T for 2 c of fat) for the first boil only

- I am not sure lengthy boiling is necessary for subsequent steps

- 2c of bacon grease makes about 12 bars of soap

- I may never buy plant oils for soap again

UPDATE: The bacon soap was absolutely delicious on the skin – super soft without leaving a film. Unfortunately, the chicken stockish smell lingered – particularly in a warm shower. I found this a little…disappointing. So I re-milled the soap – grating the bars, melting them in water in a double boiler, dousing them with tea tree essential oil, and re-pouring. I am still waiting for the soap to dry (I added too much water), but will report back when I use the first bar.

UPDATE 2: Still stinky. Like burned chicken stock. I wonder if rancidity was a problem? I had been storing my grease on the counter and certainly it would have been rancid. So I am starting over, storing grease in a container in the freezer, just in case. Will try again when I have enough grease to start the cleaning…

UPDATE 3: Still waiting to accumulate enough grease. My breakfast cooker has gone off bacon for a while now, prefering some veggie patties with his eggs. As he is the cook, I can hardly complain. MEANWHILE, when I am ready, I will try this method of cleaning the grease. Hopefully it will be less stinky.

Wow! who knew?

Jennifer,

After seeing an article on the stormwater runoff in Puget Sound on PBS (second time) this evening, I looked up information on that and you. Found your blog (obviously) and enjoyed the five recent posts. Already checked out the No Impact Man link and viewed his problem and solution video. Intend to pass info about his documentary to a local (Salem, OR) group that shows such movies, invites people involved/knowledgable with the topic, and leads discussions with the audience for all to learn more. All this to say I appreciate what you’re doing. I’ve done some personal work along these lines for a few decades and spread such information when I find people interested in the subject.

Luc

Thank you so much Luc. I really appreciate your interest and engagement!

Pingback: Bacon fat in soap? - Soap Making Forum

Pingback: kitchen grease? - Soap Making Forum

I think you just convinced me to buy organic soap from my Amish friends in Holmes country ohio. They make there own soap and sell it tooe cheap. They have flecks of rosemary and lavender in it and make it after they slaughter and render their beef and pig. Of course they have four women and their daughters (ten of them) to help and they make enough for a year or more for each family. My hats off to those that do this as routine as I cook eggs!

That’s cool Lee! Great option to have. I bet it is delicious.

I remember making soap with fats that didn’t smell wonderful- I read instructions somewhere to do one of the washes with vinegar in the water, not salt, to remove the rancid smell. It really seemed to work for the soap I made- huge batches of it about two years ago, we still have plenty.

I am determined to try again and will try the vinegar as well! Thanks!

I’m in the process of making my first batch of bacon fat soap……I “washed” it several times with water. Then did one wash with vinegar and boiled for 2 hours. Still had a funky smell so I repeated the vinegar wash and left the pot simmering on the stove for about 8 hours. I think that did it! The lard is a lovely light cream color and right now has _no_ funky smell going on.

I’m making soap as soon as the fat gets melted down and my lye dissolves completely in my Goat’s milk!

I’ll let you know how that goes!

Please do let me know!! My last batch turned out better, but not odour-free…

We own a restaurant so thought i would try to use bacon grease in my next batch of soap as it would decrease soap cost. I boiled the grease in water twice and it was very clean. I found the lard to contain some water that adhered when scooped off the water wash. I thought i could place in stainless deep pot on very low fire and have the water boil off. SO WRONG. I got a big blowout with melted lard on everything in my kitchen. Any suggestions on how to get all water out of washed lard.

I don’t think you need to get every drop off, but my lard formed a relatively solid pat that I removed and placed on a plate. Any drops on the plate I could easily pour off. The rest I didn’t worry about as I just put it into the pot to melt for soap. Was your lard very soft?

Hello.

Thanks for the fat cleaning tips. I usually just filter it and cut it half-and-half with olive oil, but I will try the salt bath.

I’ve found that using a basic goats’ milk, honey, and oatmeal recipe cuts down on the weird smells.

I have been collecting bacon grease from family and friends for a while. There is just something awesome about using it to make soap.

Hi Nolan, so you’ve not been able to completely rid the soap of stink? I’ve been wondering if it’s the smoking or whatever. Lard won’t stink, but it hasn’t been processed the way bacon is, you know?

I am just getting ready to begin hobby soap making. I started collecting bacon fat awhile back and have used to to cook potatoes. It’s great. I decided to try making some soap with it, and have been reading for weeks about the process in my spare time. I looked at http://www.soapcalc.net/calc/soapcalcwp.asp and could not find bacon fat. I want to be able to play with the superfat contents and know the lye amounts need to be very precise. Am I missing the entry for bacon fat here? If not is there another calculator for using bacon fat? Also, has anyone reported back results from using vinegar to clean the fat? Cider or white? I am excited to get started but want to get things as correct as possible the first time.

I just looked again and believe I found it. Lard pig tallow. Is this correct for bacon fat? A second opinion or more would be wonderful.

Hi Patrick,

I think that’s about as close as you’ll get. I think I used ‘lard’ (0.1388). What SAP value did you find for the tallow? Also, I’ve not heard of using vinegar to clean. PLEASE let me know how that works out for you! I was so discouraged by the residual stink of my soap. I ended up throwing it out 😦

My grandmother made bacon soap, I don’t think she even cleaned the fat. I just remember her using lye pellets, water and our saved bacon fat, and stirring it in a big pot in the back yard. My mom used the soap in the laundry as a pre-wash by rubbing the bar into stains. Until my dad cleaned the garage on day and threw it all out. Boy was mom mad.

The fat that I rendered isn’t getting any thicker? I rendered it a few times but it is still a bit runny. I guess I am making liquid soap….. What do you suggest to thicken it up?

Hm…runny doesn’t sound good! Is it straight up bacon fat or mixed with other meat fats? Also, what water are you using to render it? And are you adding salt to it?

To help remove odor, try using a mixture of baking soda and flour. Add water to the mixture and roll them into balls about half the size of hush puppies. This should absorb some of the odor. Fry the balls in the fat. You can also put fresh herbs (I like infusing it with vanilla bean or fresh ginger) in the oil while cooking the balls. Then wash the fat with water again. Allow it to solidify in the fridge, then in the freezer. The fat will rise to the top as a layer, then poor off the water. Repeat, if needed.

Perhaps the “stink” is part ran its, but perrhaps it’s something that happens when you get the bacon? When frying there’s no way to not burn the fat. That’s what frying is.

Sometimes my family gets big bags of bacon ends and pieces. If you don’t need perfect strips, it’s actually far more cost effective to just buy these odd chunks and slice it up yourself. But you will find some chunks that are literally all fat. What if you rendered those chunks down in a water bath in a crock pot? Low heat for a few hours. Then the fat wouldn’t be burning and you may be able to effectively skirt the stinkiness issue!

I also wondered if it’s smoke – as in ‘smoked bacon’…

Dear Soapmakers,

Regarding the Lye/Soap Calculator, we would like to invite you to try our Soap Calculator on our web-site.

the 1° Soap Calculator able to calculate also the % of Glycerin inside your soap !

We published our updated new Soap Calculator here: http://www.soapworld.biz/soap-calculator-handmade-soap.html

Good Soap !

Hi there,

Just wanted to let you know that we are launching a post this week highlighting the best DIY soap recipes we could find, and we are featuring your Bacon recipe with a link to the post.

We also really enjoyed your photos and wanted to get your permission to use one of them in our post?

Thanks for sharing your recipe – keep up the good work! 🙂

-Kat

Well, probably late now, but permission granted. Thanks!

Heartily enjoyed your post. Been making cold process soap out of home rendered lard for about a year now. I use water drawn directly from lake Erie inmy lye solution because I’m trying to raise awareness that household cleaning products can effect our watershed. Wondering if you’ve ever seen a layer of unsaponified lard form on top of the soap and what might cause that? Anyway, good to read your post. My mom used imperial margerine too in our southwestern Ontario home and saved jars of bacon grease as well

Heather – I wonder if our moms knew each other! About the layer on top – it is probably ‘soda ash’ (NaCO3) from unprocessed lye interacting with atmospheric CO2. Where do you get your lard?